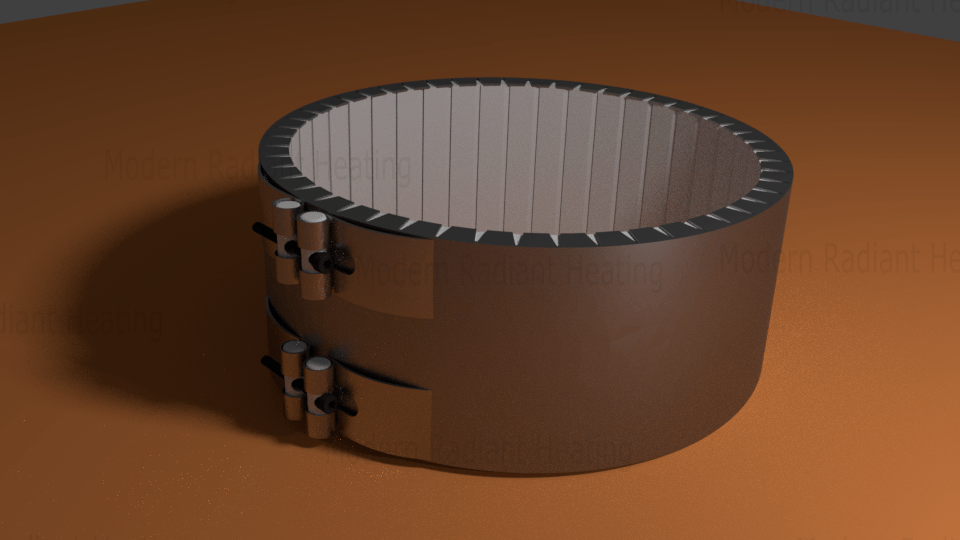

| Product | Ceramic Band Heaters |

|---|---|

| Sheath Material | SS |

| Insulation | Ceramic |

| Voltage | 220V/440V |

| Power | 250W~5500W |

The ceramic band heater is a cutting-edge product that offers exceptional heating performance and durability. Designed with advanced ceramic material, this heater ensures efficient heat transfer and uniform temperature distribution. Its compact size and low profile design allow for easy installation and integration into various industrial applications. The high-quality construction includes a stainless steel sheath, which provides excellent corrosion resistance and enhances the heater’s overall lifespan. With its customizable options such as watt density, voltage, and termination styles, this ceramic band heater can be tailored to meet specific customer requirements. Whether used in plastic injection molding machines or extruders, this heater delivers consistent heat output, ensuring optimal productivity and product quality. In summary, the ceramic band heater is a reliable solution that offers superior performance and flexibility for any industrial heating application.

Specification and Ordering

In order to specify your Ceramic band heater, you are required to have some dimensions in handy as follows or you can also specify by the part no, or drawing, if any.

1. Diameter (Φ)

The most important is the diameter. The barrel diameter or the cylinder diameter is required to be specified to order your heater or if you have an existing heater, you can measure its inner diameter.

2. Length or Width

You are also required to measure the lenght/width of your heater in order to specify or order your heater. The length/width is measured in mm or inch.

3. Power in Watts

Heater consumes power and power is measured in Watts. Hence you are also required to mention your power ratting in watt and applied voltage. The common voltage applied in India is 230V ac. However, These heater can be designed and manufactured at any other voltage and for single phase or three phase system.

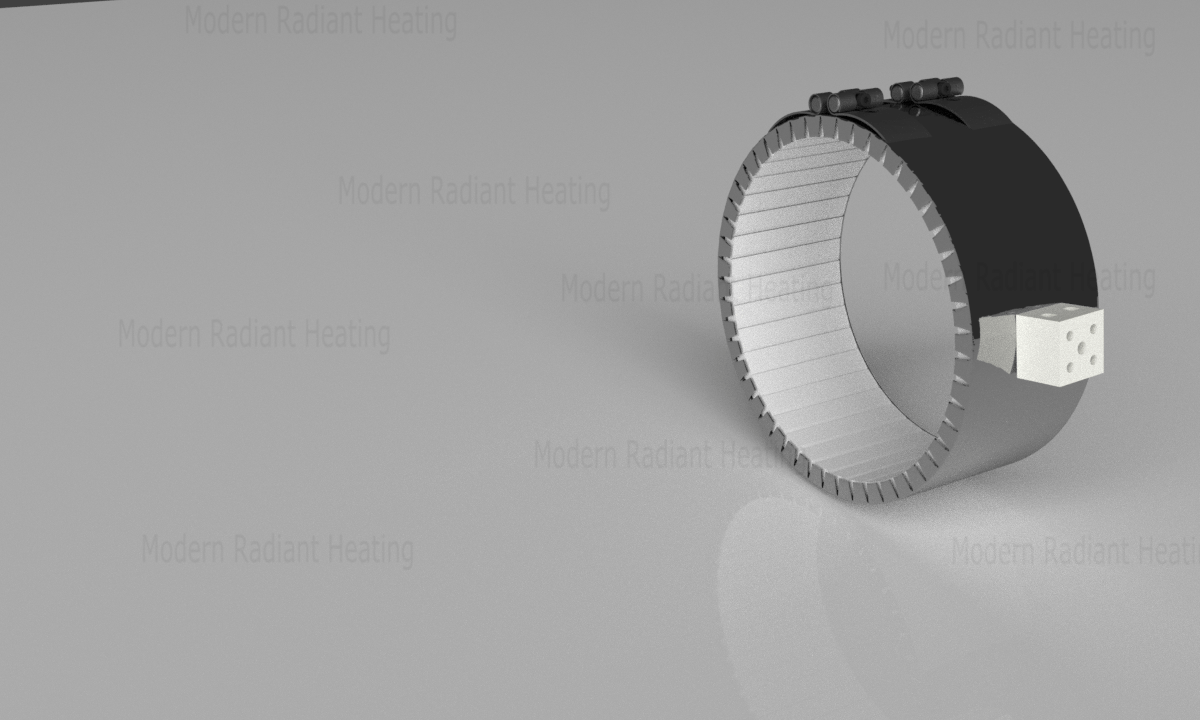

3. End connections

Ceramic band heaters have various end connections, from where you can connect it with mains. The Most common are the Ceramic block connector, the wire connection with protective metal box and the wire with metal coundit.

If you have any questions, Feel free to reach out us at our phone or email or have a visit at our office. We will be glad to help you in selecting your heater.