| Product | Bobbin Heater |

|---|---|

| Sheath Material | Stainless Steel, Titanium |

| Insulation | Ceramic |

| Voltage | 220V/440V |

| Power | 500W~9KW |

Quick Connect

Modern Radiant Heating

Plot no 9, Sai-Baba compound, Behind Arihant Complex, Mugat dyeing lane, Besides Kiran Dyeing/Industries, Udhna, Surat, Gujarat, India

Request a quote

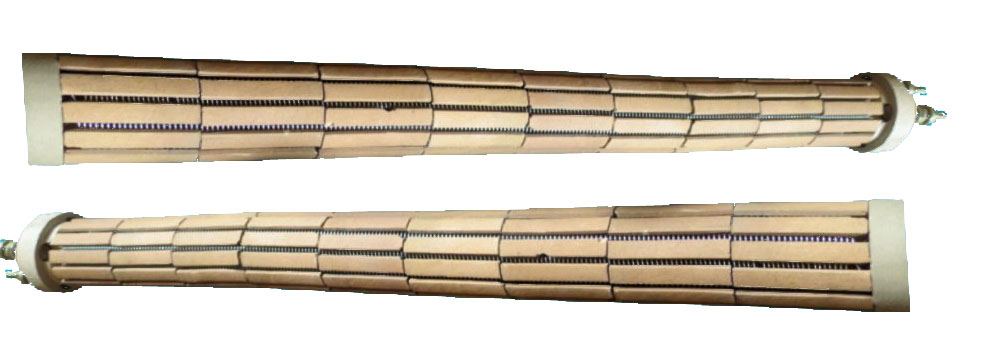

We are a known manufacturer and supplier of Bobbin or porcelain heaters and are manufacturing these heater for years.

Bobbin heater needs no introduction to those who uses it. These heater finds use for heating Air, Water, Oils, or other Process fluids like petroleum products.

These heaters are also used for heating space as radiant heaters.

These heater comes in various Diameters, Length and Power ratings and offers versatile heating solutions for various applications.

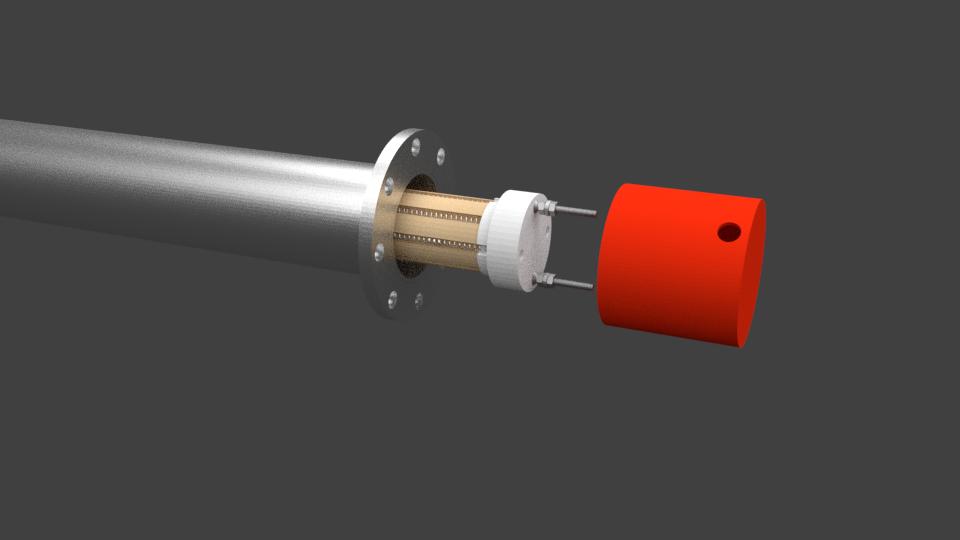

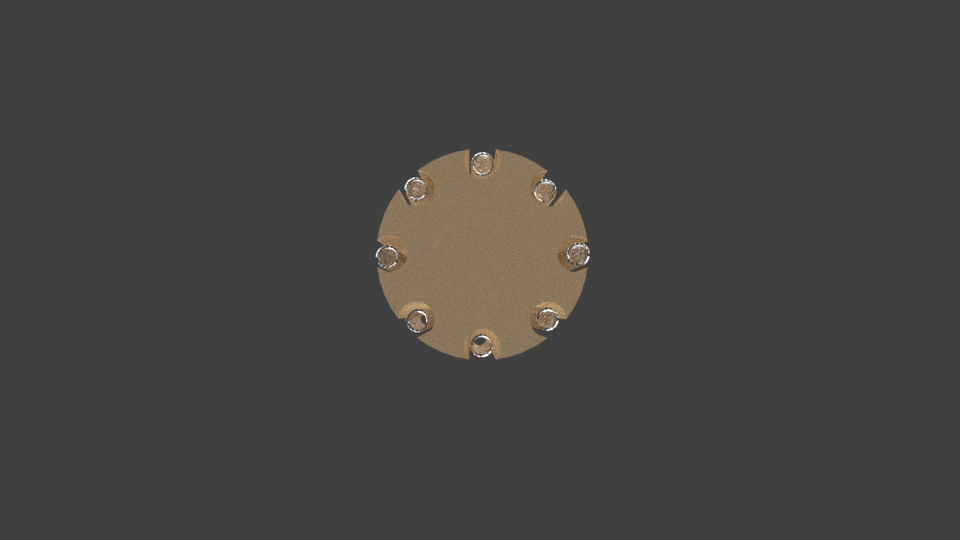

The main advantage in using bobbin heater in heating process fluid is that, in case a bobbin heater fails, The tank is not required to be emptied. A bobbin heater serves as an indirect means of heating. Take an example of the image below.

The bobbin heater is simply inserted in protruded pipe brazed to tank flange. It is flexible, and required practically no downtime in changing this heaters.

Whether you require a custom-made solution or need assistance in selecting the appropriate bobbin heater for your specific requirements, our team of experts is readily available to guide you through every step of the process.

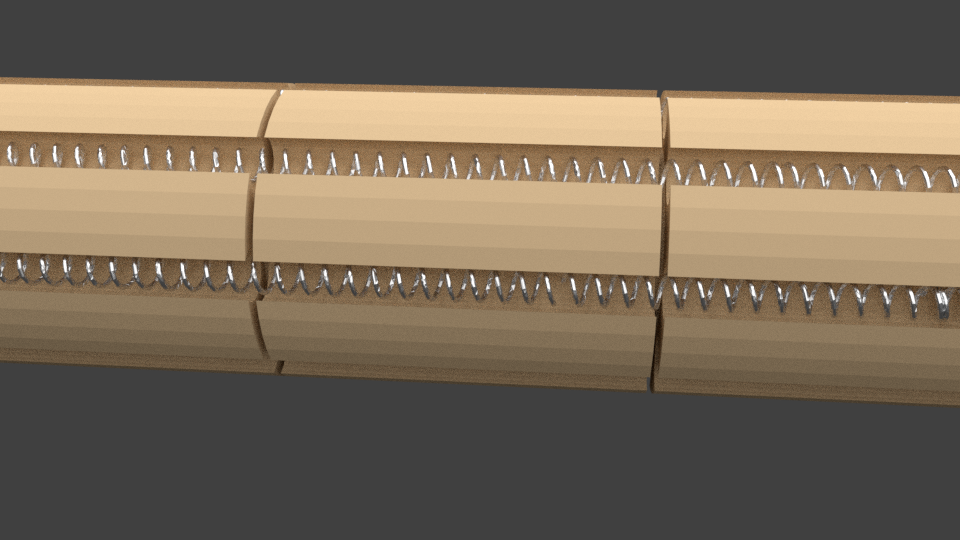

Construction Features

Bobbin heaters are made by passing resistive wires through meticulously designed groves or holes. This manufacturing technique ensures maximum efficiency and heat transfer while maintaining optimal performance.

The groves or holes serve as a guide for the placement and alignment of these wires, ensuring that they are positioned correctly to deliver consistent heating. The design of bobbin heaters allows for easy installation and replacement if needed, making them a reliable choice for various industrial applications. Additionally, high-quality materials used to make these heaters to sustain high temperature, frequent temperature cycling and thermal shocks guarantees durability and longevity.

Advantages

- Bobbin heaters are designed with a high surface-area-to-volume ratio, allowing for faster and uniform heat distribution. This results in effective heat transfer and energy savings.

- Bobbin heaters are highly durable and can withstand extreme temperatures without compromising their performance.

- Bobbin heaters offer versatility as they can be customized to fit specific requirements by adjusting the length, diameter, wattage, voltage, and sheath material. This adaptability makes bobbin heaters suitable for various industries such as oil and gas, chemical processing, food production, and more.

- Easy installation and maintenance as bobbin heaters typically require minimal effort to set up or replace

Application

- Heating liquids, gases, or solids inside tanks, vats, or process equipment

- Oil heating in hydraulic power packs

- Water heating in boiler systems

- Air dehumidification in drying chambers

- Plastic resin melting in extruders

- Steam generation for sterilization purposes