| Product | Tube Heater |

|---|---|

| Sheath Material | SS 304, SS 316, Incoloy |

| Insulation | MgO |

| Voltage | 220V/440V |

| Power | 750W~80KW |

Need tube heater? You reached the right place. You can choose us as your reliable vendor. Introducing us as a reliable tube heater manufacturer in India where quality and performance meets its expectation. We are an experienced manufacturer and are into manufacturing these heaters from 10+ years. With years of experience we can guide you in selecting suitable tube heater with various Sheath materials, their wattage and Maximum temperature they can be expose to. We build and manufacture various types of Tube heater for your application such as Corrugation Heaters for cartoon boxed, Calendering for Textiles produce or Heating of fluids among various others. If you need any assistance, feel free to contact us and we will try to give our best to assist you.

No compromise on quality

As we are in the industry for quite a long time, we never compromise on our quality. Our customer’s feedback and satisfaction means a lot for us. We ensure quality at the very beginning of releasing each manufacturing orders. It is not just about the raw materials, but we strive to maintain quality at each level whether it is about taking orders, selecting raw materials, manufacturing, testing and delivering on time. Each step is taken care for a great product and a great user experience.

Salient features of our Tube Heaters:

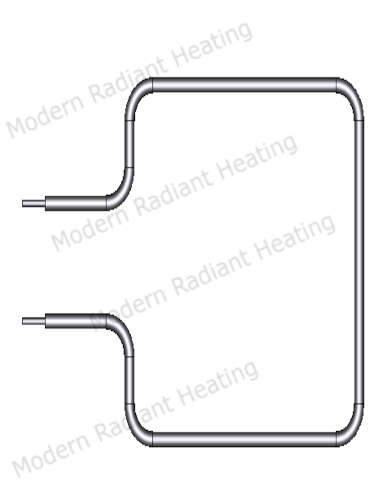

Common Tubular Heating element Bending Designs:

Some of the most commonly design form of tubular heating elements is are as follows:

M shaped Heater

M shaped Heater Double U shaped Heater

Double U shaped Heater U and L shaped Heater

U and L shaped Heater Two Side L shaped Heater

Two Side L shaped Heater Frame Shaped Heater

Frame Shaped Heater Heater for plate design 1

Heater for plate design 1 Heater For Plate Design 2

Heater For Plate Design 2 Hot Plate Heater

Hot Plate Heater U shaped Heater

U shaped Heater

How to order Tube Heater?

Ordering tube heater is simple. If this is the first time you are ordering or about to use tube heater feel free to connect us over phone or email or best visit us at our office. We will be happy to assist your application. To order your tube heater, it is best if you provide a detailed drawing of it. If don’t have a drawing, you may send us your current heater or sample. We will manufacture the same for you with same specification.

If your tube heater is simply a straight tube with no bends, then the main specification required to give an order is:

- Diameter of Heating Element (Usually Φ8mm or Φ11mm or Φ16mm)

- Total Length in inch

- Cooling length, Both side in Inches

- Heating Length in Inches

- Maximum Operating Temperature

- Operating Voltage

- Wattage or Watt Density

- Sheath Material (Usually Stainless Steel)

- Type of form Straight or Profiled

- Termination type (Usually Threaded Stud)

- Type of Sealant (Usually epoxy, RTV Silicon Sealant)

Use and maintenance

Using and maintaining Tube heater is easy. However, some points should be noted and should be followed to make your tube heater work long without premature failure

- Always properly tighten the terminal nut or otherwise, a loose connection could result into sparking at the terminal. This could result in melting of terminal pin and hence a fail heater.

- Always use a ring lug for securing the connection. A Ring lug with proper pressure ensures a large contact area and thus eases the path of current to flow.

- A Tube Heater when brazed with flange and immersed in a fluid acts as an immersion heater. There is no problem as when the fluid comes in contact with the sheath. But the fluid shouldn’t come into contact with the terminal as it may result in Short-circuiting or burning of the fluid due to electric arcing. Hence, proper leak should be identified prior to energizing such heaters.

- Proper cleaning of sheath material should be done at regular interval, as Dust, contaminates, or Deposition of salts(as in the case of water heating element) may hamper the flow of heat or thus may result into your heater failure.

- During installation proper sized copper wire should be used for powering tube heaters. As a rule of thumb, for 1 Amps of current, the minimum required wire size (in sqmm) is 0.166. Thus if your heater draws 6 Amps of current, the minimum required wire size would be 6 amps x 0.166 = 0.996 ~ 1sqmm. If you don’t know how much amps your heater would draw, you can use our Basic Ohms law calculator, assuming you heater is designed for single phase supply, or you can use three Phase Star and three Phase Delta Calculator for 3 phase Supply.